Silicone raw materials skyrocket? How to find the fulcrum of quality and price to maintain lasting competitiveness? Zhengzhou Zhongyuan Silande offers advice for you: how to choose a cost-effective external glue for framed insulating glass

2021-08-20

How to choose a cost-effective outer sealant for framed hollow glass

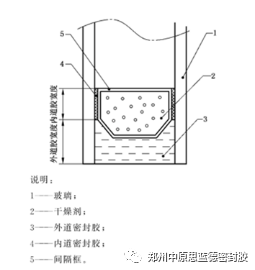

Insulating glass was introduced into my country in the 1980s, and has been widely used in my country's construction, transportation, refrigeration and other industries due to its excellent energy-saving features such as heat insulation, sound insulation, and anti-frost fog. As a key component of the insulating glass structure, the quality of the external sealant plays a crucial role in the quality and service life of the insulating glass. At present, the main structure of the outer channel sealant for framed hollow glass mainly includes two categories: silicone and polysulfide. The two have different structures and different performances.

In the current market competition environment where silicone raw materials are chasing up and hard to find, how to reasonably select the external sealant for framed hollow glass will determine whether the company has lasting competitiveness in the industry. Quality is the life of an enterprise, and the quality of sealant plays a crucial role in the quality and service life of insulating glass. Reasonable selection of materials is to find a balance between quality and price.

This article analyzes the performance and cost of the external sealant, and guides customers and friends how to choose a cost-effective external sealant for framed hollow glass.

Factors affecting the service life of insulating glass

01

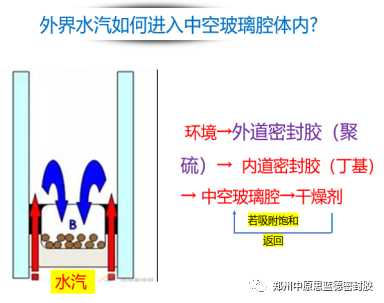

The service life of insulating glass is directly related to the quality of edge sealing materials (such as spacers, desiccants, sealants) and the production process of insulating glass: when the spacers, desiccants and production processes are certain, the inherent characteristics of the outer sealant The tightness directly affects the service life of insulating glass.

Cost-effectiveness of polysulfide and silicone insulating glass sealants

02

The structure of the two materials is different, which is mainly reflected in the obvious difference in sealing performance. The data are shown in Table 1.

Table 1 Comparison of sealing data of typical domestic polysulfide and silicone insulating glass sealants

|

|||||||||||

From the data in the above table, it is known that the sealing property of polysulfide insulating glass sealant is better than that of silicone insulating glass sealant.

At the same time, Clause 3.2 of Appendix C of GB/T 11944-2012 "Insulating Glass" stipulates: "When the water vapor permeability of the sealant is >15g·m-2·d-1, the width of the outer sealant should be ≥7mm; The water vapor permeability of ≤15 g m-2 d-1, the width of the outer sealant should be ≥ 5mm,

According to this standard, when preparing insulating glass of the same specification, the outer sealant using polysulfide insulating glass sealant is 2mm smaller than the silicone insulating glass sealant, which has the same sealing effect.

图1 中空玻璃结构示意图

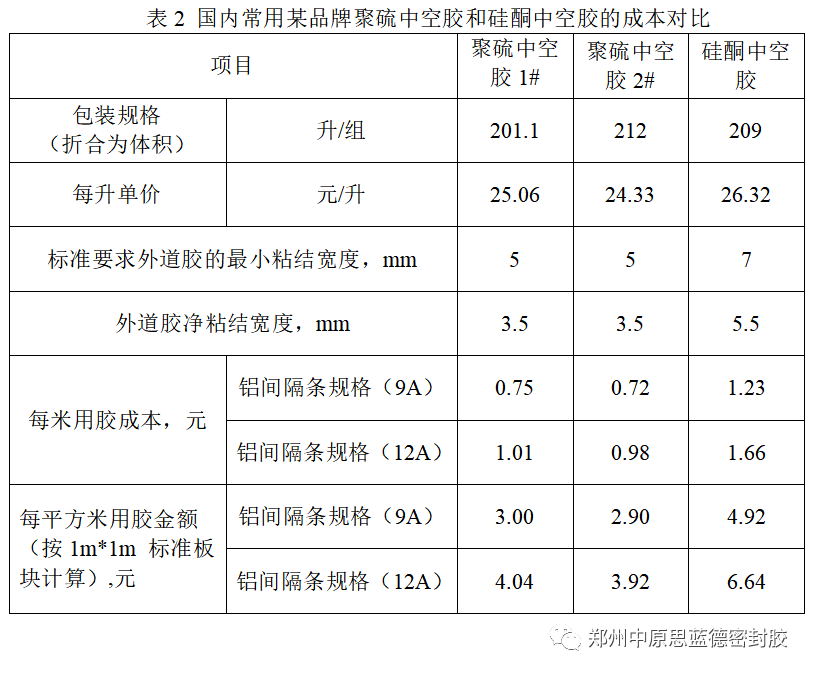

现以国内市场常用某品牌的聚硫、硅酮中空玻璃密封胶进行成本对比分析

郑州中原思蓝德高科股份有限公司

表2: 国内常用某品牌聚硫中空胶和硅酮中空胶的成本对比

Remarks: When calculating, the height of the adhesive layer in the 9A aluminum spacer structure is calculated as 8.5mm, and the height of the adhesive layer in the 12A aluminum spacer structure is calculated as 11.5mm.

As can be seen from Table 2, for the same specifications of insulating glass, the cost of the outer sealant is lower when polysulfide insulating glass sealant is used.

At present, under the circumstance that the price of domestic silicone raw materials is rising like a rocket, and it is difficult to obtain a "ticket", the selection of polysulfide insulating adhesive for framed insulating glass can not only ensure the sealing life of insulating glass, but also reduce cost pressure and cost-effectiveness. Higher! Compared with other low-end insulating glass sealants on the market, the quality is more reliable! More durable and competitive!

Real-time News

—

2022-07-20

Copyright©Zhengzhou Zhongyuan Silande High Technology Co., Ltd.